Client : Hitachi Rail

HICSE

Hitachi Information Control Systems Europe Ltd.

My Role

I joined this project for 3 months as Design Lead.

I created the UX UI design solution with HICSE team to demonstrate a signal communication idea. I worked with one junior UX UI designer from Hitachi Vantara.

Problem

In order to work safely, lines must be blocked. The current line block process lacks information efficiency, using paper forms and phone calls.

Track maintenance work is delayed when line block requests are rejected, often without enough feedback or reason. On rejection, there is uncertainty about what will happen next.

Human intuition is heavily involved in the approval process and opinion often supercedes data. The process is one of time consuming negotiation and validation that often needs to be repeated multiple times. Human error occurs, and trains are sometimes mistakenly routed into line blocks when communication is ineffective.

Solution

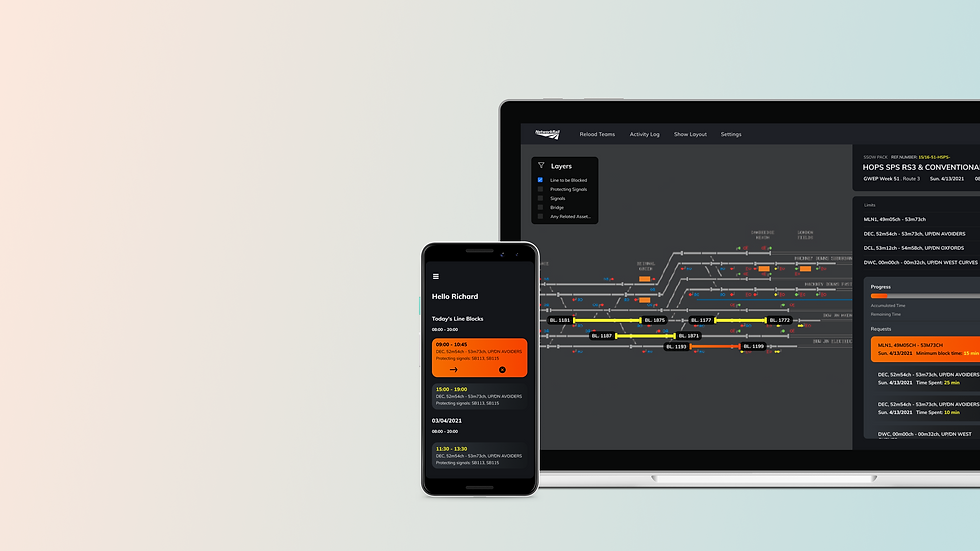

Our solution is a digital line block system that helps to improve both track worker and signaller confidence with multiple safety layers. Interactive features allow users to avoid choosing wrong signals or protections and support their communication to release tension and misunderstanding.

Signaller

Track worker

.png)

Research and design process

Define limitations

Current disadvantages

AS-IS and TO-BE

Maximise benefit of using data and digital platform.

Minimise emotional barrier and Improve safety

Define basic needs

Support opportunities

Design prototype

A clickable prototype

Define opportunity

Development opportunities

Feedback

How the client & user will adopt this system and how this will improve the safety and minimise the process.

Define limitations

No additional ‘situational awareness’

All relevant information transmission is limited to the conversation between TW and Signaller. There is no additional means of knowing: where TWs are, how many, what work planned / eqpt with them, best access point (start / end of work), nearest welfare, current operational status (e.g. trains running to TT?), how many other trains the signaller is having to deal with, what would be the optimal line block duration, or optimal slot in the TT (time of day).

No additional assurances

All actions are subject to the momentary decisions of an individual signaller, regardless of their workload.

A physical reminder is placed on decision buttons in manual areas.

No second line of defence

No verification of initial decision, no ongoing monitoring of potential changes / additional demands. No support activity at all outside of the single individual: no ‘parking sensors’ let alone ‘automated braking’.

Need support opportunity

Decision support:

-

Which signals make that block safe

-

How many trains to divert; how much time to deal with them / priority

Action support:

-

Visual reminder of location and blocked-time left (prob already have?)

-

Audible alarm, or signal prevention, of any mis-applied train path instructions

Workload support:

-

Quicker to grant line block and check its in right place.

-

Less stress – know line block is safe

-

Less to write down and record long hand – ‘push button’ info capture

Workload support:

-

Shared map of location and number of workers

-

Shared visual of signal block ‘red area’

-

Shared task order and progress (Hence likelihood of finishing on time)

-

Automatic (auditable) record of all actions: requests / granting / handback / work completed

Development opportunity

Data driven insights:

-

Work planned / completed – performance; factors affecting etc.

-

Prediction of ideal blockage length and TT space for different tasks

Decision integration support:

-

Order of workplan (Ellipse interface?)

-

Workbank App?? https://www.arup.com/projects/wessex-workbank-app#

Verification support:

-

Automated recording of all work: automated safety audit / close call trigger / review sessions

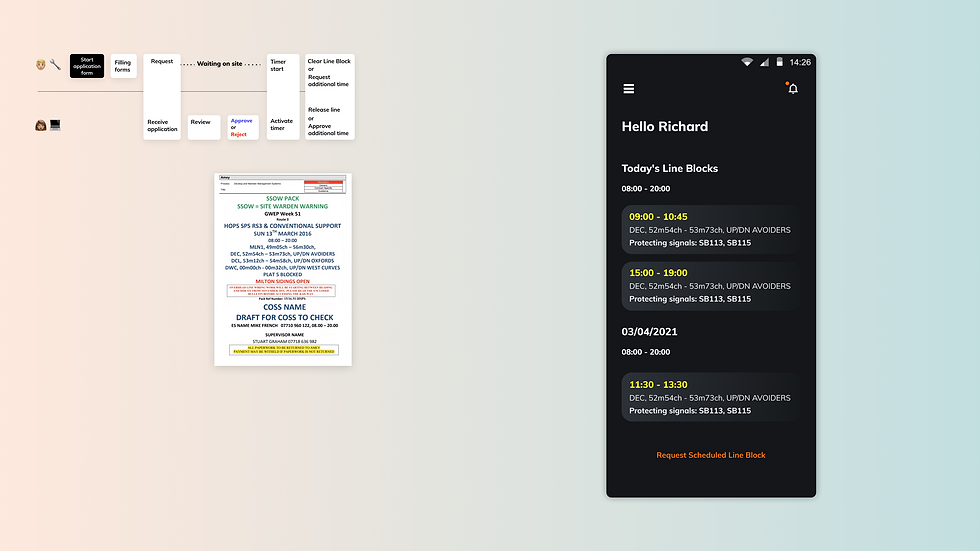

Evaluate problem and define TO-BE

We evaluated our research about opportunity and TO-BE system and MVP solution together at workshop.

AS-IS in detail

TO-BE

The proposed solution addresses these issues by:

-

Formalising the request for and granting of protection for Line Blocks.

-

Provide information to the Signaller about the signals placed to danger that protect Line Blocks.

-

Provide information to Trackside Workers about the status of the protection.

-

Formalising the hand-back of Line Blocks and the removal of protection, with an efficient digital record.

-

Provide a digital solution that is flexible / scalable and avoids the need to deploy line-side equipment.

A Clickable Prototype

Work package

The equivalent data to the existing paper work package is displayed in an easy to digest form on the home screen in the new mobile app.

The users start request process by selecting one of the plans.

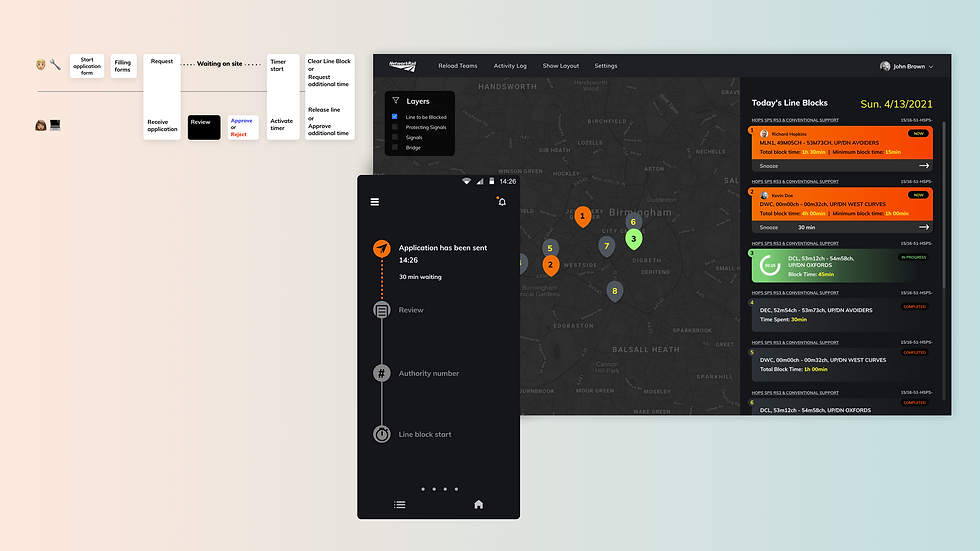

Safety first request process

The interactive map allows a user to confirm the signal locations and autofills the form. Old fashioned map reading skills are still utilised to confirm that the COSS understands their location and the location of the signals.

The user can resize and scroll the map to and select signal simply by tapping.

Digital forms

The contents in the forms is prioritised automatically based on the work type.

Time request

The signaller can provide the time between trains which can be as little as a few minutes at times, including the time required to clear the line.

If a task takes longer to finish, tasks need to be broken down into short chunks. Every one of those chunks will need enough time to complete so that the track workers can safely clear the tracks. The user can fill the minimum required time to maintain the working momentum, e.g. a 15 minute minimum.

Document review

In order to provide a transition from existing work practices to the new digital way-of-working the app generates a version of the existing paper based form which can be reviewed by both the COSS and the signaller.

Overview/Dashboard

Keeping track of the current status of line block requests and the overall view of active line blocks are important requirements for the COSS and Signaller.

Here we present two views showing the status indicators available to both individuals, so that they can track progress and the current situation regarding line blocks.

Waiting to be confirmed

The COSS is kept informed of the current status of the line block as the signaller reviews it.

Review Process

1. The COSS can see the allocated signaller and review time

Review Process

2. The COSS recieves an update when the signaller starts to review the request form.

Review Process

3. The COSS release an authority number.

Timer / Approval

A signaller release an authority number and the timer screen apears. This mean soon the line block will be activated.

Timer interaction

Releasing a line block

The line block is only ended when the COSS confirms to the signaller that the work is finished.

If the work is not complete the line block is suspended and the COSS can request more time (within the maximum time allowed) to complete the work. The active line block process repeats.

When the work is finished, the data relating to the line block is recorded and archived.

Feedback

The client really liked and positive about the reduces workflow and effective communication.But the system need a parallel communication support in case the internet connectivity issue. The user want to see the heat map of internet connected area and adoptable area's track length to calculate 5G investment planning.

Learning

Complex system is not always bad but a clear communication is important.

Sometimes it is an optimised way to maintain the maximum safety in legacy company.

Adopting the technology is not the main blocker in digital transformation.

Changing culture and perception is more difficult and requires investment.

However if the team work collectively it rapidly changes the legacy culture and open to see a digital intervention.